DENISON, Iowa — The way Dee and Randy Kruse harvest corn

is something of a family tradition.

“We’ve been doing it for a long time,” Dee said.

Their two-row New Holland corn picker belonged to

Randy’s dad. Dee’s father still picks corn on the ear, but

other than him, Dee said she doesn’t know of anyone else in

the area who still harvests that way.

Dee and Randy still pick corn on the ear on their

operation near Denison because it’s a cheaper and more

efficient way to feed their cattle.

Grinding corn on the ear provides feed from the corn and

roughage from the cob.

“If you feed straight shell corn, then you have to feed

hay or something else along with it because cattle need roughage

to keep their rumens going,” Dee Kruse said. “When we grind

the cobs, it gives roughage for the cattle, so it’s a lot less

expense for us to do.”

She said storing and grinding ear corn would not be as

efficient for large cattle operations, but it works well for

their 14-head operation.

“Luckily, we still have our corncrib up, so that’s

where it goes,” she said.

Corncribs on most other farms have been torn down so the

ground could be farmed or to be replaced by machine sheds.

Loading the corn into the corncrib requires a corn elevator

instead of an auger; the elevator has to be moved around, and

heavy chutes have to be attached to direct the ears of corn into

the corncrib.

A downside to harvesting the old-fashioned way is that the

technology is starting to disappear.

Parts for the corn picker are becoming harder to find.

“We go to a junkyard and hope they have the corn picker

there and the part isn’t gone already, but most of the time it

is,” she said.

The same is true of the elevator.

“You don’t find many of them around anymore either,”

Dee said.

Picking and storing the corn involves a lot of manual

labor.

“It’s a lot of hard work,” Dee said. “It’s not

for the wimpy.”

Randy Kruse pulls an old two-row corn

picker, which removes the corn from the

stalks and augers it into a wagon.

Corn is dumped into the Kruses’

corncrib. The corn will dry there and later

be ground up for livestock feed.

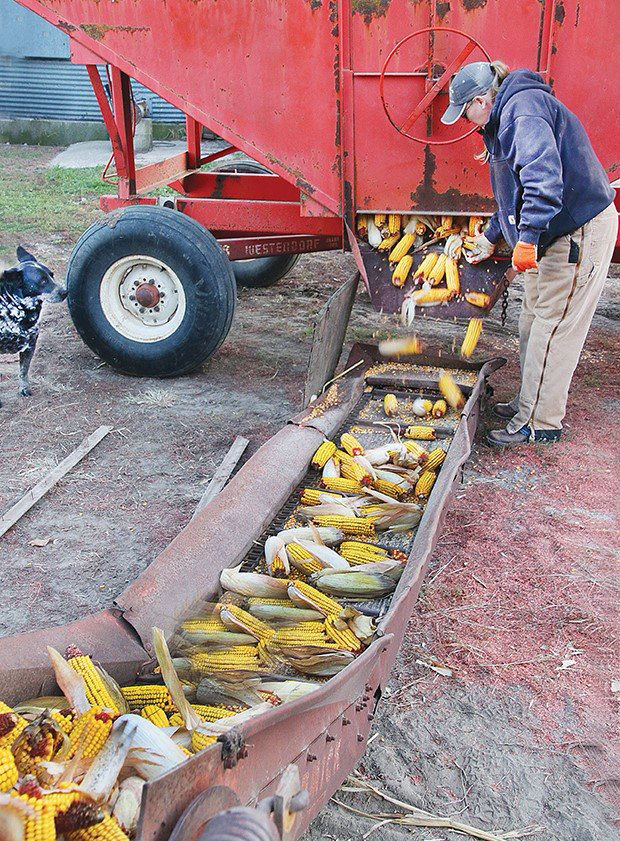

A rugged piece of equipment used to

transport the ear corn from the wagon is

this elevator, which brings the product into

the second floor of a corncrib. The elevator

and the corncrib are both becoming rare

sights in the farming industry.

Dayna Crandall, a family friend, helps

with the harvest of ear corn at the Randy

and Dee Kruse farm. She unloads a wagon of

corn into a corncrib as Daisy, the family

dog, keeps a watchful eye on everything.

Dee Kruse climbs out of the seat of a

four-row corn combine to touch base with her

husband, Randy, and friend, Dayna Crandell.

At this point, the three-person crew is

stopping to change equipment to a two-row,

pull-behind corn picker.

Ear corn, rarely harvested this way

today, can sneak out through the spaces

between wooden slats in the corncrib and

pile up a bit outside — but none of the

corn goes to waste.

DENISON, Iowa — The way Dee and Randy Kruse harvest corn

is something of a family tradition.

“We’ve been doing it for a long time,” Dee said.

Their two-row New Holland corn picker belonged to

Randy’s dad. Dee’s father still picks corn on the

ear, but other than him, Dee said she doesn’t know of

anyone else in the area who still harvests that way.

Dee and Randy still pick corn on the ear on their

operation near Denison because it’s a cheaper and more

efficient way to feed their cattle.

Grinding corn on the ear provides feed from the corn and

roughage from the cob.

“If you feed straight shell corn, then you have to feed

hay or something else along with it because cattle need

roughage to keep their rumens going,” Dee Kruse said.

“When we grind the cobs, it gives roughage for the

cattle, so it’s a lot less expense for us to do.”

She said storing and grinding ear corn would not be as

efficient for large cattle operations, but it works well

for their 14-head operation.

“Luckily, we still have our corncrib up, so that’s

where it goes,” she said.

Corncribs on most other farms have been torn down so the

ground could be farmed or to be replaced by machine

sheds. Loading the corn into the corncrib requires a

corn elevator instead of an auger; the elevator has to

be moved around, and heavy chutes have to be attached to

direct the ears of corn into the corncrib.

A downside to harvesting the old-fashioned way is that the

technology is starting to disappear.

Parts for the corn picker are becoming harder to find.

“We go to a junkyard and hope they have the corn picker

there and the part isn’t gone already, but most of the

time it is,” she said.

The same is true of the elevator.

“You don’t find many of them around anymore either,”

Dee said.

Picking and storing the corn involves a lot of manual

labor.

“It’s a lot of hard work,” Dee said. “It’s not

for the wimpy.”

More than a

century ago the son of a German immigrant built a sturdy barn in Sarpy

County. It weathered storms, blistering heat and freezing cold. Now the

land it sat on will be turned over to a developer, and the barn will

weather that, too. On Tuesday crews moved the old barn 3 miles southeast

from where it sat in the county’s rolling hills near 114th Street and

Schram Road. Ron Tex said his great-grandfather built the four-story barn

in 1903 on a farm where the family grew corn and raised cattle and horses.

Tex said he and other family members sold the 160 acres. Preliminary plans

call for 335 homes on the land under development by Boyer Young

Development Co., according to the City of Papillion. But Tex could not let

the barn die with the sale. “It’s the last part of the memories,’’

he said. Tex, 63, remembers seeing a news clipping that said 300 people

turned out for a dance at the barn after it was built at the turn of the

century. In recent years the barn has been used for storage and will

continue in that role at its new spot. Tex has lived in a ranch home on

the property and crews also moved it Tuesday, along with a machine shed.

Crews from Ensor Movers Inc. used hydraulic jacks and steel beams to lift

the barn off its foundation. The beams were set on a rolling platform that

served as a trailer for the move. A similar process was used for the house

and shed. Tex said the barn is in excellent shape. It got a new roof and

paint job about seven years ago and has not required any major work to

keep it up. Ryan Baltensperger, owner of Ensor, said that because the barn

is in good structural condition, it was well-suited for the move. He said

his Nebraska-based business moves a couple of barns a year in the region.

Semitrailer trucks towed the three structures at a top speed of 8 mph.

Moving the barn and other structures took about 4½ hours, with the crew

getting them in place by about 1:30 p.m. Baltensperger said that’s a

good pace for moving three structures, even if just a few miles. Workers

from the Omaha Public Power District required time to temporarily drop or

raise some power lines above the road so the barn could pass through. The

house and the barn are now on land Tex owns in the county along Fairview

Road. The shed was moved to his son’s property nearby. Tex said the move

went well and he’s especially relieved that the barn is safely at its

new location. He said he never got the chance to meet his

great-grandfather, but knows he’d be proud that his barn lives on.

|

|